Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

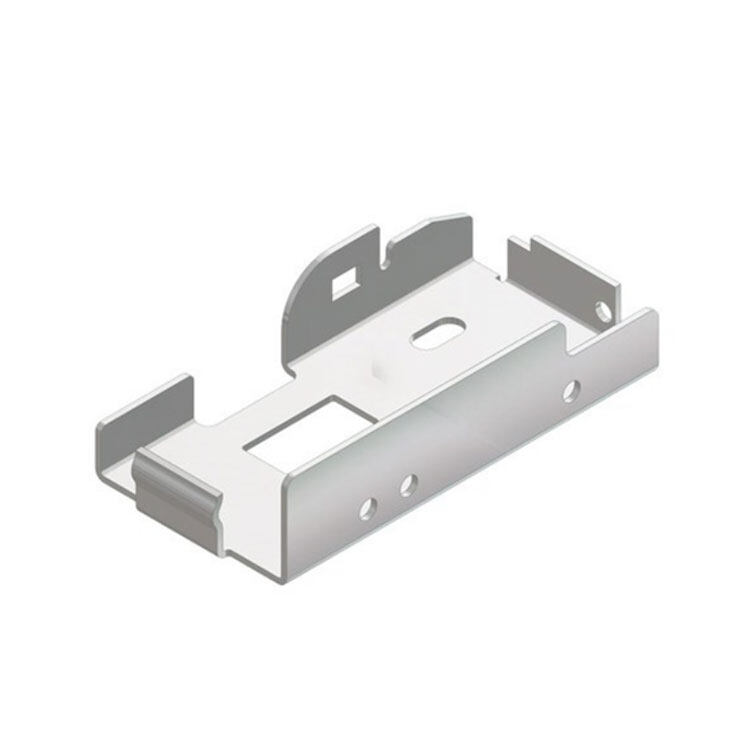

Stamping Part

Stamping parts are formed by applying external force to plates, strips, pipes and profiles by presses and molds to cause plastic deformation or separation to obtain workpieces (stamping parts) of required shape and size. Stamping and forging belong to plastic processing (or pressure processing) and are collectively called forging. The blanks for stamping are mainly hot-rolled and cold-rolled steel sheets and strips.

Stamping Part

Presses and molds are used to manufacture stamping parts by applying external force to plates, strips, pipes, and profiles in order to separate or distort the plastic and produce workpieces with the desired shape and size. Forging, which includes stamping, is a type of plastic processing (also known as pressure processing). Steel sheets and strips that have been hot- and cold-rolled are typically used as stamping blanks.

The Standard Specification of Stamping Part

|

Material |

Aluminum, Copper, Stainless steel, Iron, PE, PVC, ABS, Nylon, etc. |

|

Processing |

CNC Turning, Milling, drilling, auto lathe, tapping, bushing, surface treatment, etc. |

|

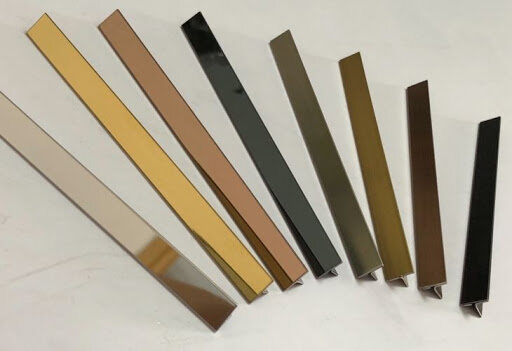

Surface Treatment |

Polishing, general/hard/color oxidation, surface chamfering, tempering, Sandblasting, Metal Plating, Polishing, Painting, Powder coating, Brushing , Silk-screen , Laser Engraving etc. |

|

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

|

Logo |

Silk print, Laser marking |

|

Size |

Accept custom size. |

|

Color |

White, black, silver, red, grey, Pantone and RAL, etc |

|

Drawing format |

DWG, DXF, STEP, IGS, 3Ds, STL, SKP, Al, PDF, JPG, Draft. |

|

Sample lead time |

No surface treatment, 1-3 workdays. Require surface treatment, 3-5 workdays. |

The features of Stamping Part